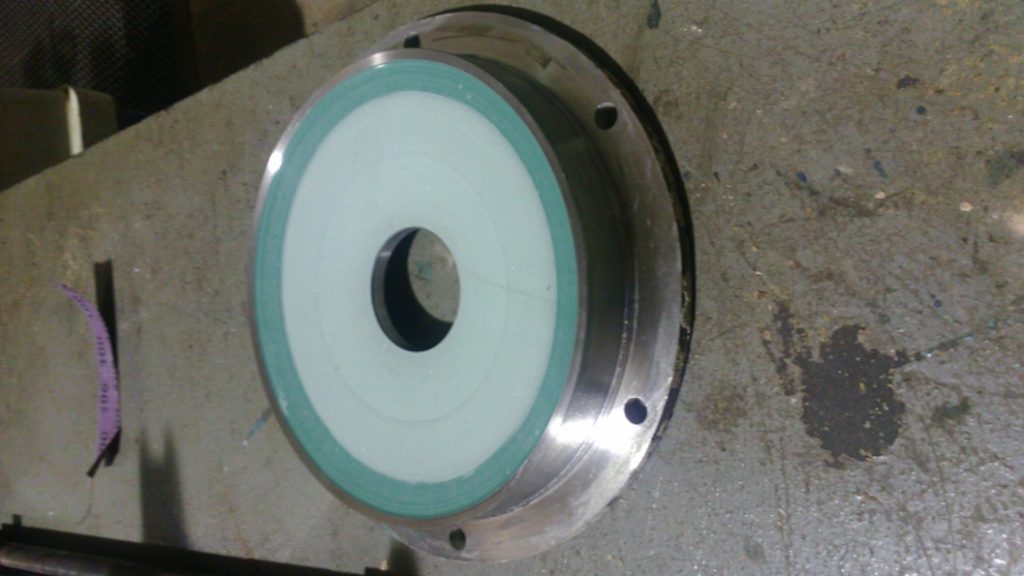

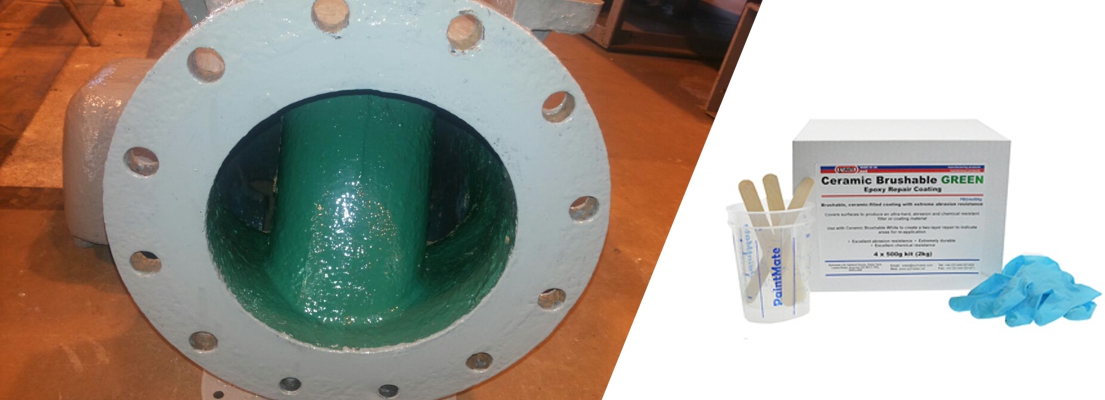

Ceramic Brushable Green Abrasion Resistant Epoxy Coating

Ceramic Brushable Green is a ceramic-filled, green coloured, abrasion resistant epoxy coating brush applied to metal, wood and plastic surfaces. It is reinforced with silicone carbide, curing to form an ultra-smooth, hard-wearing outer layer which extends the lifespan of parts and machinery by protecting and sealing against abrasion and wear.

The silicone carbide in Ceramic Brushable Green gives the cured material ultimate hardness and high resistance to abrasion. Coating new or repaired parts and systems with it creates an external shield which prevents wear, corrosion, chemical attack, erosion and pitting damaging the original substate.

Ceramic Brushable Green is also used to provide surfaces with a smooth finish, improving the efficiency of systems such as chutes by reducing friction and making clean up more straightforward. It is applied to top coat rougher repair compounds like WearShield Epoxy Paste.

The low-friction, abrasion resistant finish makes Ceramic Brushable Green an ideal epoxy coating for protecting equipment in mills, mines and other abrasive industries.

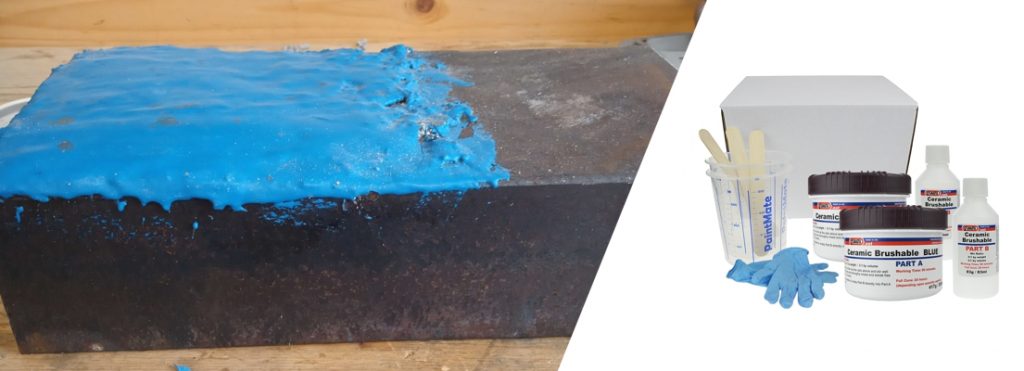

When used in conjunction with Ceramic Brushable Blue, a two-layer wear indicator coating can be created. Areas requiring renewed protection are identified when the colour of the lower coating begins showing through the upper.

Ceramic Brushable Green comes with a 90-minute gel time as standard, allowing large quantities to be mixed and carefully applied without the threat of premature curing. A faster version with a 45-minute gel time is available upon request. For more information, please contact Sylmasta.

Ceramic Brushable Green Epoxy Coating Details

Before applying Ceramic Brushable Green, surfaces should be free of paint, rust and grime before being roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Ceramic Brushable Green should be applied as soon as the preparation procedure is completed. Part A and Part B are mixed at a 3:1 ratio by volume or a 5:1 ratio by weight.

To ease the mixing process, the Ceramic Brushable Part A container has enough room to dispense all Part B into, enabling it to be applied with a brush straight from the container.

The epoxy is brush applied and each coating should be 0.5-1mm thick. To ensure a pinhole-free coating, at least two coats are needed.

Ceramic Brushable Green has a gel time of 90 minutes. The re-coating time between coats is approximately 5–8 hours after applying. A full cure is achieved 24 hours after the final coat.

To determine the quantity of Ceramic Brushable Green needed for a specific pipe repair application, please go to the Repair Calculator Tab and enter your repair data.

The light consistency of Ceramic Brushable Green makes it easy to mix and apply with little sag. It is virtually odourless, with no unpleasant smell, can be easily machined and is temperature resistant to 150°C.

To create a two-layer wear indicator coating, a topcoat of one colour of Ceramic Brushable is applied over a base coat of another colour.

When the base coat colour begins to show through, it is an indication of high-wear. Another coating of Ceramic Brushable should be added to maintain suitable levels of protection for the original substrate.

Benefits of Ceramic Brushable Green

- Easily mixed and applied – just paint onto a surface using a brush

- Protects against abrasion, corrosion and cavitation

- Creates an ultra-smooth, glass-like finish to all surfaces

- Extremely hard setting

- Longer working time allows for complex jobs to be carried out

Applications

- Protecting new equipment from wear and corrosion

- Providing a final topcoat over repaired surfaces

- Protecting silos, chutes, mills, pumps, impeller blades, valves, fan blades, metal castings, tanks and other machine parts in abrasive environments

- Increasing resistance against corrosion and chemical attack

- Creating a two-layer wear indicator coating when used with Ceramic Brushable Blue

- Reinforcing castings by filling voids

Technical Data

| Data | |

| Work Time | 90 minutes |

| Re-coat Time | 4-6 hours |

| Full Cure | 24 hours |

| Shore D Hardness | 90 |

| Compressive Strength | 111 MPa |

| Max Service Temp | 150°C |

Product Codes

| Code | Paste Quantity |

| PBGR-500g | 500g |

| PBGR-4x500g | 2kg (4 x 500g) |

| PBGR-2kg | 2kg |

| PBGR-5kg | 5kg |

TDS Downloads

Ceramic Brushable Green Epoxy Coating Repair Calculator

The below Liquid Metal & Ceramic Brushable Coverage Calculator can be used to determine the quantity of Ceramic Brushable Green needed to coat a specific pipe, cylinder or surface area.

Enter the diameter of the pipe or the width of the repair area in millimetres, the length of the repair area and the coating thickness of Ceramic Brushable Green to be applied. The wastage percentage is how much Ceramic Brushable Green you expect to lose in the application.

Once you have entered your data, the calculator will show the amount of Ceramic Brushable Green required in kilograms. If you require further help with an application, please fill in the report form at the bottom of the calculation and a Sylmasta technician will get back to you.

Ceramic Brushable Green Epoxy Coating Case Studies

Case Study: Power Station Repair Extensive Damage to Alloy 20 Pump Lid Caused by Impeller

Case Study: Water Treatment Plant in Puerto Rico Repair Worn Pump Extracting from a Well

Case Study: Corroded Tank Repair at a Puerto Rico Pharmaceutical Plant

Case Study: Repair of Metal Blades in Bakery Flour Mixers Suffering From Heavy Corrosion

Please use the form to enquire about the price and availability of

Ceramic Brushable Green Epoxy Coating

Related Abrasion and Wear Protection Products

Fast-working version of WearShield with a 5-minute work time, a functional cure of 45 minutes and a three-hour full cure. It allows impact and wear protection measures to be made and equipment put back into service more quickly, minimising downtime and disruption.

Work Time: 5 minutes

Functional Cure: 45 minutes

Max Service Temp: 105ºC

Ceramic Supergrade Epoxy Paste

Silicone carbide-filled epoxy paste which forms an ultra-smooth, low friction material highly resistant to abrasion. It rebuilds existing parts damaged by wear and is applied to new equipment to create a hardened protective shell, extending the lifespan of machinery.

Work Time: 60 minutes

Functional Cure: 90 minutes

Max Service Temp: 130ºC

Ceramic Brushable Blue Epoxy Coating

Blue-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC