Case Study: Repair of a Leaking 150mm Steel 90 Degree Elbow Bend at a Quarry Wash Plant

A quarry group in the United Kingdom previously sealed all leaks at their sites using pipe repair clamps until a pinhole leak appeared 50mm away from a 90 degree elbow in a 150mm diameter steel pipe. It forced them to seek an alternative, more versatile solution capable of application around bends and other difficult geometries.

Case Study Overview

Site Quarry wash plant

Location Hampshire, UK

Repair Type No pressure pipe repair

Defect Pinhole leak in 150mm steel pipe elbow bend

Repair Products

Superfast Steel Epoxy Putty, SylWrap HD Pipe Repair Bandage,

SylWrap Standard Pipe Repair Kit

Case Study PDF

Case Study Details

The 150mm steel pipe was located in the wash plant of the quarry, passing across a lake. Wear and tear had caused a pinhole leak to appear in the line around 50mm away from a 90 degree elbow bend, leading foul water to escape into the lake below.

Normally when pipework failed on site, the quarry would fit a pipe repair clamp over the problem area. This was not possible in this case because of the location of the leak area being so close to the elbow.

Seeking a more versatile repair method capable of being effective on the bend, the quarry contacted Sylmasta. Once it was established that pressure could be easily shut off, a SylWrap Standard Pipe Repair Kit for sealing offline leaks was delivered to the site.

The pipe was cleaned as best it could be before the repair began. Superfast Steel Epoxy Putty Stick was used to seal the pinhole. The required amount of putty was cut from the stick and kneaded by hand.

After around two minutes of mixing and whilst still soft, the putty was pushed into the hole in the pipe. Within 10 minutes it had hardened, forming a material as hard as steel which now filled the pinhole.

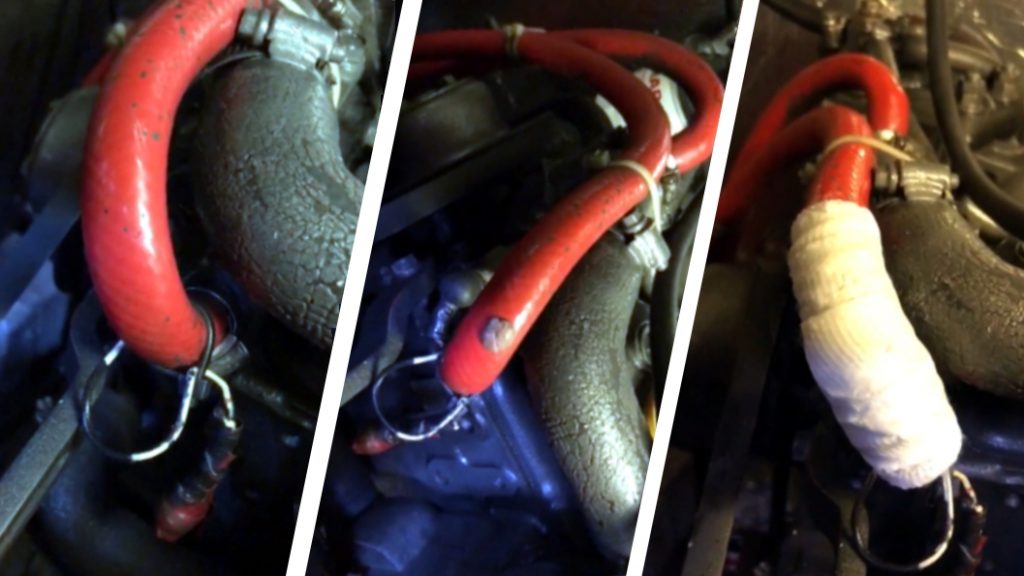

To further reinforce the repair, a SylWrap HD Pipe Repair Bandage was applied around the leaking section. SylWrap HD is a composite repair wrap with a water activated resin which sets rock hard in minutes.

SylWrap was wrapped and smoothed around the pipe, curing to form an impact resistant sleeve. This would help protect the pipe from future breakages, a common occurrence due to the abrasive nature of operations at the quarry.

Although the quarry wash plant pipe operated at relatively low pressure, using Superfast Steel and SylWrap HD in conjunction created a pipe repair resistant to 30 bar.

The entire application was completed in under 30 minutes by a member of the operations team at the quarry. No training was required; they simply followed the instructions provided with the Kit to make a permanent pipe elbow bend repair.

Since the repair, the quarry group have taken further stock of SylWrap Pipe Kits for use across their sites. They know them to be capable of making more versatile repairs than heavy, bulky pipe repair clamps.

Products Used

Superfast Steel

Fast working steel epoxy putty used to seal the pinhole leak in the pipe

SylWrap HD Bandage

Composite wrap applied over the sealed leak, reinforcing the repair and protecting the pipe

Standard Pipe Repair Kit

Kit containing Superfast Steel and SylWrap HD for permanent offline pipe repair

Related Case Studies

Case Study: Repair of Underground Clay Drainage Pipe Cracked During Building Work

Case Study: Burst Copper Pipe Repair in Portable Horse & Dog Shower Unit

Case Study: Boat Owner Repairs Pinhole Leak in Rubber Hose Connected to Engine

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com