Video: How to seal a cast iron pipe with pressure on

Sylmasta use CrackSeal Sealant and SylWrap HD Pipe Repair Bandage to seal a horizontal split in a cast iron pipe whilst pressure remained on and water leaked through. The repair was also pressure tested and successfully held 10 bar with no sign of any leakage or deformation.

About this Pipe Repair Video

This demonstration video was filmed at Sylmasta HQ to test the live leak repair capability and pressure resistance of CrackSeal Pipe Sealant when used to seal a crack in a cast iron pipe.

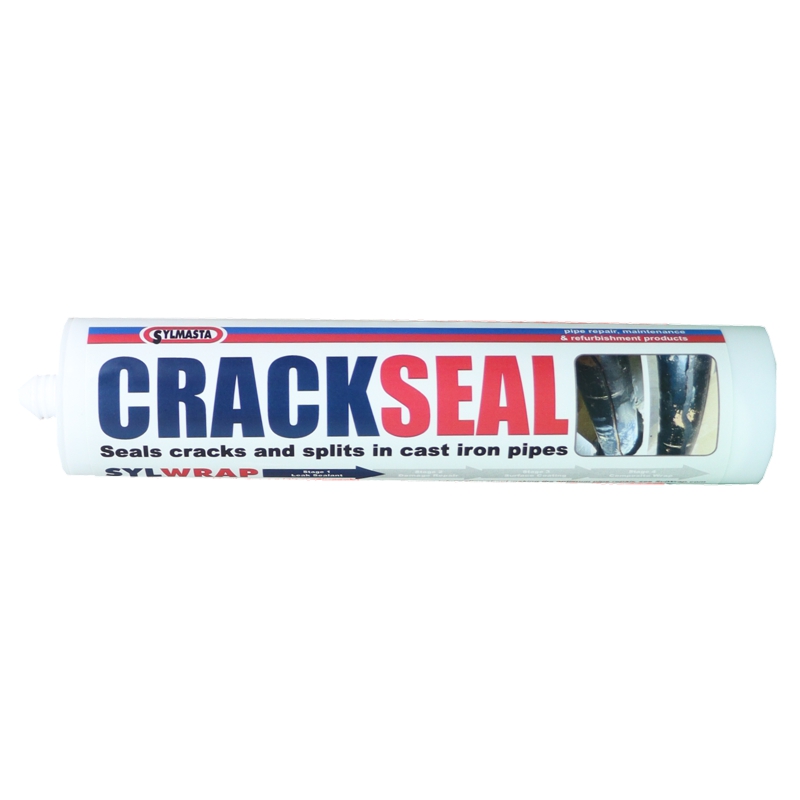

CrackSeal is a moisture curing pipe sealant used to quickly and easily repair cracks and splits in cast iron waste, drain and soil pipes. It is also effective on other pipe materials, including steel and concrete-lined pipework.

We cut a horizontal split into a test rig and set pressure so that a steady stream of water was leaking through. CrackSeal was then used to repair the damage.

Using a standard sealant gun, we extruded CrackSeal into the crack until it was totally filled. The sealant began to harden almost instantly. It easily contained the live leak and prevented any more water leaking through.

CrackSeal forms a skin in 10 minutes. Before this happened, we worked quickly to smooth it off with a plastic spatula. This helped increase the surface area of the repair and improved the adhesion between the sealant and the pipe.

After CrackSeal had been applied, the pipe was left for 24 hours. This allowed the sealant to reach maximum properties. We then tested the repair.

Pressure through the rig was steadily increased to 10 bar. No water leaked through and there was no deformation of CrackSeal, indicating a successful repair.

For added reinforcement, we applied a SylWrap HD Pipe Repair Bandage across the entire repair area. SylWrap HD is composite repair wrap with a water activated resin.

It was wrapped and smoothed around the cast iron pipe, curing within minutes to form a rock hard impact resistant sleeve encompassing the leak area.

This made for a stronger repair and a permanent solution with even greater pressure resistance beyond the 10 bar CrackSeal alone had withstood.

CrackSeal and SylWrap HD can be purchased together for making permanent live leak repairs as part of the SylWrap Cast Iron Pipe Repair Kit.

The Kit also includes Superfast Steel Epoxy Putty. Superfast Steel is a fast-working epoxy putty mixed by hand and forced into holes too large to be filled with CrackSeal. It cures to a waterproof, steel-like material in 10 minutes.

Cast Iron Pipe Repair Products

CrackSeal Sealant

Sealant extruded directly into cracks in pipework, where it hardens almost instantly

SylWrap HD Bandage

Composite repair wrap sets rock hard to create reinforced sleeve around pipework

Cast Iron Pipe Repair Kit

Contains CrackSeal, SylWrap HD and Superfast Steel for a single cast iron pipe repair

Drain & Waste Pipe Repair Kit

Specialist kit containing enough products for multiple drain, waste and sewer pipe repairs

Related Case Study

Case Study: Cast Iron Waste Pipe U-Bend Crack Repair Above Hospital Corridor

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com