Ceramic Supergrade Abrasion Resistant Epoxy Paste

Ceramic Supergrade is a silicone-carbide filled epoxy paste. It is applied to metal, wood and most plastics to create a repair which is ultra-smooth, low friction and highly resistant to abrasion. It increases wear resistance and extends the lifespan of machinery and parts in abrasive environments.

The silicone-carbide in Ceramic Supergrade offers ultimate surface hardness. It is applied using a trowel to protect new equipment against wear, corrosion and chemical attack.

Once cured, Ceramic Supergrade sets to an ultra-smooth, reinforced, blue-coloured layer covering the original substrate. The smoothness of Ceramic Supergrade ensures less friction when parts rub and collide together.

This makes it ideal for protecting equipment in mills, mines and other industries where abrasion is commonplace. The toughened outer shell provided by Ceramic Supergrade takes the brunt of the impact rather than the machine part or surface.

Ceramic Supergrade can be used to rebuild areas of heavy damage to existing systems by creating a new, hardened surface over parts. It repairs silos, chutes, impeller blades, fans, metal castings, pumps, valves and tanks. It is moisture tolerant and easy to mix and apply.

A 60-minute gel time allows for large quantities to be mixed and carefully applied without the threat of premature curing. Because of its work time, Sylmasta recommend Ceramic Supergrade for applications at higher ambient temperatures.

Ceramic Supergrade Abrasion Resistant Epoxy Paste Details

Before applying Ceramic Supergrade, surfaces should be free of paint, rust and grime. The substrate should then be roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Ceramic Supergrade should be applied as soon as the preparation procedure is completed. Part A and Part B are mixed together at a 2:1 ratio by weight or volume.

The epoxy paste is then spread over the area requiring repair using a putty knife. Ceramic Supergrade should be pushed in firmly to ensure maximum contact and to avoid trapping air between the paste and the surface.

Ceramic Supergrade is temperature resistant to 130°C. It has a gel time of 60 minutes and achieves a full cure in 24 hours. It is thixotropic, meaning it will not sag.

It is virtually odourless, with no unpleasant smell compared to other epoxy pastes. Its light consistency makes it easier to mix than stiff, heavy traditional epoxy pastes.

Once cured, repairs made with Ceramic Supergrade can be top coated for further reinforcement with Ceramic Brushable Blue Epoxy Coating. Ceramic Brushable provides another ultra-smooth layer of protection and can be used alongside Ceramic Brushable Green to create a wear indicator coat.

Benefits of Ceramic Supergrade Epoxy Paste

- Ultra-smooth finish creates low friction surface

- Silicone carbide-filled for increases resistance to abrasion

- Moisture tolerant

- Easy to mix and apply with a long work time for larger applications

- Effective on metal, wood and most plastics

Applications

- Extending the lifespan of equipment by protecting it against abrasion, corrosion and chemical attack

- Rebuilding worn and damaged surfaces and machinery

- Repairing heavy damage to shafts, silos, chutes

- Repairing valves, fan blades, metal castings and tank

Technical Data

| Data | |

| Work Time | 60 minutes |

| Full Cure | 24 hours |

| Shore D Hardness | 90 |

| Compressive Strength | 100 MPa |

| Max Service Temp | 130°C |

Product Codes

| Code | Paste Quantity |

| PCG-500g | 500g |

| PCG-4x500g | 2kg (4 x 500g) |

| PCG-2kg | 2kg |

| PCG-5kg | 5kg |

| PCG-37.5kg | 37.5kg |

TDS Downloads

Ceramic Supergrade Abrasion Resistant Epoxy Paste Case Studies

Case Study: Refurbishment & Repair of Power Plant Condenser Unit Deformed by Corrosion

Case Study: Heavily Damaged Metal Machinery Repair Saves a Puerto Rico Ball Mill $60 million

Please use the form to enquire about the price and availability of

Ceramic Supergrade Abrasion Resistant Epoxy Paste

Related Abrasion Protection Products

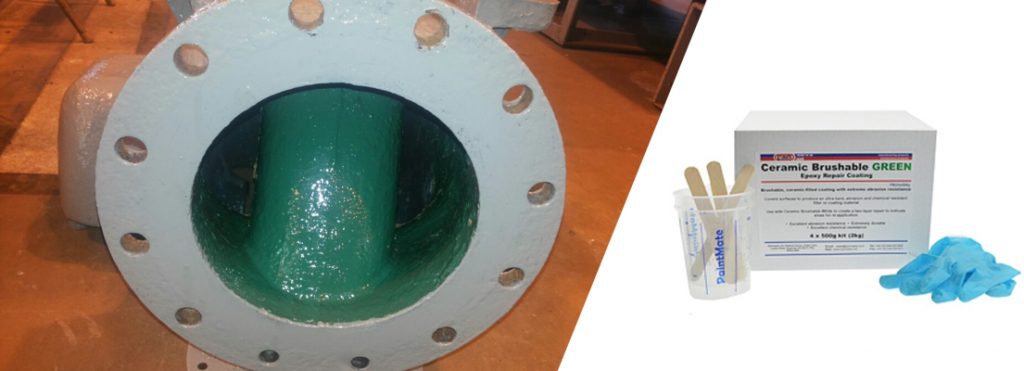

Ceramic Brushable Green Epoxy Coating

Green-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC

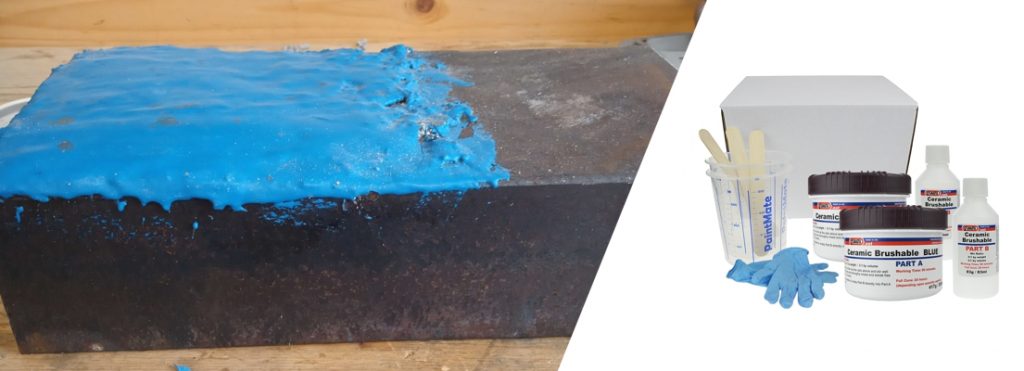

Ceramic Brushable Blue Epoxy Coating

Blue-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC

Fast-working version of WearShield with a 5-minute work time, a functional cure of 45 minutes and a three-hour full cure. It allows impact and wear protection measures to be made and equipment put back into service more quickly, minimising downtime and disruption.

Work Time: 5 minutes

Functional Cure: 45 minutes

Max Service Temp: 105ºC