Sylmasta Pipe Repair, Maintenance and Refurbishment Case Studies

The following Case Studies highlight pipe repair, maintenance and refurbishment applications which Sylmasta products have been used in, from major infrastructure projects to leak sealing in domestic kitchens and bathrooms.

If you have any questions about any Sylmasta products or require help with an application of your own, please contact Sylmasta and a technician will be happy to assist you.

Case Study: 3 Metre Section of Corroded Steel Gas Pipe in CHP System Repair & Refurbishment

A pipe carrying natural gas in a combined heat and power system is refurbished after water trapped between the line and a badly installed PVC tape caused heavy corrosion

Case Study: Leaking Welded Saddle Joint Repair on 150mm Steel Pipe at Pumping House

A leaking saddle joint welded on a 150mm steel pipe connected to a pumping house in Malaysia is sealed by building a repair up and over a 20mm step between the line and the joint

Case Study: Burst Copper Pipe Repair in Portable Horse & Dog Shower Unit

Copper pipes in a number of horse and dog showers which burst when temperatures in the UK went as low as -15°C are repaired, returning the units to service in under 30 minutes

Case Study: Seawater Storage Tank Floor Repair at Gas Processing Plant in Saudi Arabia

Gaps which had developed between rubber sheets covering the floor of a seawater storage tank at a gas plant are filled in to protect the exposed concrete coating the bottom of the tank

Case Study: Live Leak Repair of 150mm Cement Coated Steel Pipe on Water Network in Mexico

A live leak repair is made to an underground cement coated steel pipe supplying potable water in Mexico after removal of the outer shell revealed a 80mm split in the line

Case Study: Power Station Repair Extensive Damage to Alloy 20 Pump Lid Caused by Impeller

A pump lid made from Alloy 20 at a power station treatment plant undergoes repair instead of a $4000 replacement after extensive damage was caused by a falling impeller

Case Study: Trenchless Pipe Installation Protection of 150mm Steel Natural Gas Pipeline

Welded joints on a natural gas pipeline are wrapped with SylShield for protection prior to a trenchless installation underneath a stream and road in Czechia

Case Study: Repair of Leaking Stainless Steel Pipe Inside Farm Biodigester Tank

A leaking stainless steel pipe damaged inside a biodigester tank at a pig farm is sealed after an initial repair attempt via patch welding was discovered to have failed

Case Study: Reinforced Welded Corners in Chromic Acid Tank Sealed Using SylWrap HD

SylWrap HD provides enhanced sealing security against possible leaks left after the welding in place of new corners during the reinforcement of a corroded chromic acid tank

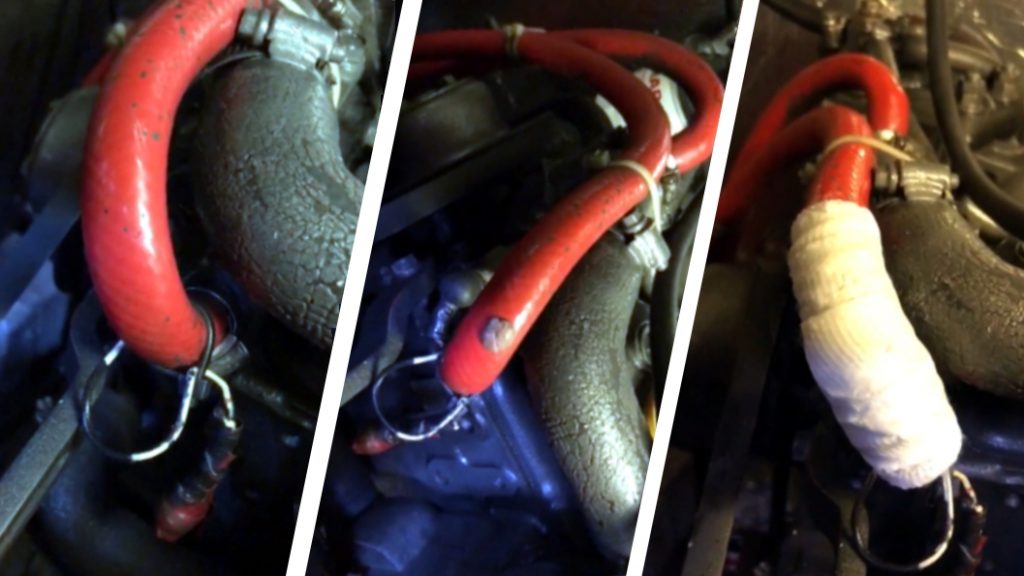

Case Study: Boat Owner Repairs Pinhole Leak in Rubber Hose Connected to Engine

A hardened rubber hose playing a vital role in cooling a boat engine undergoes repair after developing a pinhole leak in an area of the vessel which was extremely difficult to access

Case Study: Environment Agency Repair Crack in Underwater Wall Between River & Trout Farm

The Environment Agency permanently seal a 700mm long crack in an underwater wall discovered when abnormal levels of water were monitored passing from a river into a trout farm

Case Study: Fence Spurs Suffering from Concrete Cancer Filler Repair Using Epoxy Putty

Spurs suffering from concrete cancer which began disintegrating during the replacement of a trellis fence are repaired and rebuilt using Sylmasta AB Original Epoxy Putty

Case Study: Wastewater Treatment Plant Seal Pipe Flange Against Tree Root Ingress

After a tree root penetrated an underground 1800mm pipe between flange plates, a wastewater treatment plant seal the line and protect it against future ingress

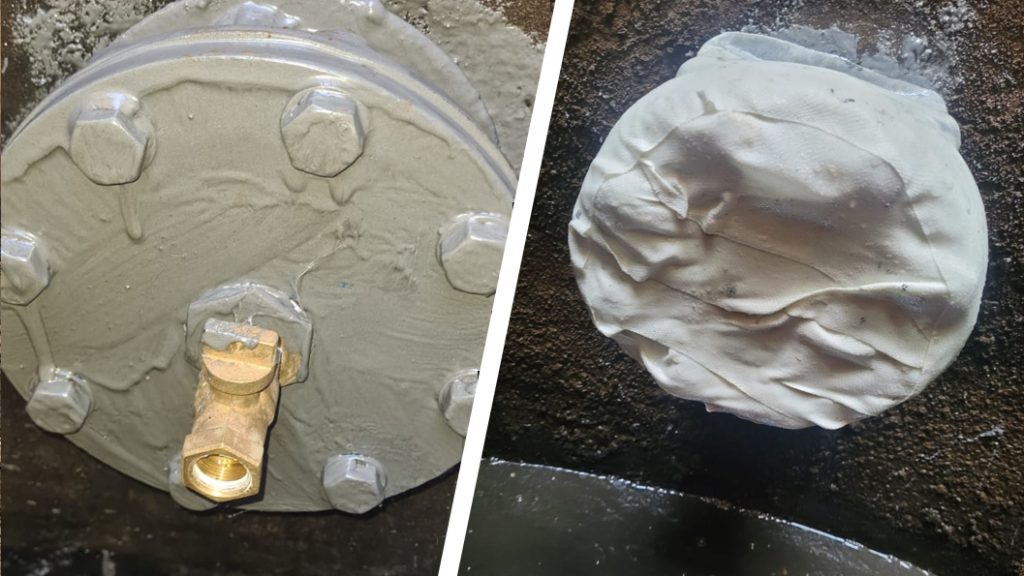

Case Study: Pipe Capping of Decommissioned Underground Drainage System at Landfill Site

A landfill site in Wales encapsulates a pipe stub and flange plate after capping to ensure a decommissioned drainage system could not release toxic leachate into the environment

Case Study: Repair of Leaking 350mm Effluent Pipe Running out to Sea Underneath Salt Marshes

An effluent pipe running under salt marshes and out to sea is sealed in a logistically challenging repair which had to be completed in an eight hour window whilst the tide was out

Case Study: Reinforcement of Heavily Corroded Steel Pipe to Avoid Future Leak Repair

A heavily corroded section of steel pipe is reinforced, helping a site to avoid a future breach which would have required a costly and disruptive leak repair or replacement of the line

Case Study: Permanent Mortar and Pestle Repair Made Using Epoxy Adhesive

A granite pestle cracked into two parts is permanently bonded back together, giving its owner many more happy years of preparing ingredients using their favourite kitchen tool

Case Study: Permanent Anti Slip Solution to Protect Workers When Standing on Helicopter Skids

The Puerto Rico Power Authority create permanent anti slip surfaces for the legs of helicopters in their fleet on which workers stand during repair and maintenance of equipment

Case Study: Oil Refinery Repair of a Leaking Underground GRP Seawater Return Pipe

A leaking underground 3000mm GRP seawater return line is partially excavated and sealed in an epoxy putty repair at an oil refinery, cutting downtime from several weeks to two days

Case Study: Protection of Wooden Entrance Gates at an Estate in Scotland Against Rotting

Upgrades to an estate entrance gate created the potential for wooden slats to rot at the base until a waterproof, bevelled edge was formed from epoxy putty to prevent water pooling

Case Study: Repair & Refurbishment of Corroded 20 Metre Long Porth Pipe Bridge

A dilapidated, corrosion-covered 300mm steel pipe crossing a 20 metre bridge over the Rhonda River is repaired and refurbished at a fraction of the cost of replacement

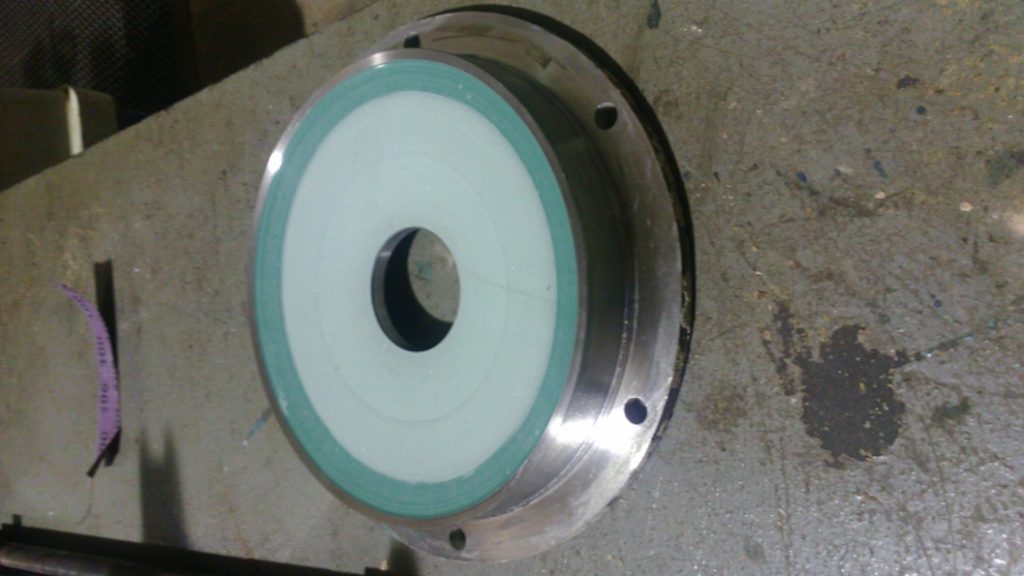

Case Study: Water Treatment Plant in Puerto Rico Repair Worn Pump Extracting from a Well

Ceramic Brushable Green provides a long-term repair solution for a pump which had become badly worn due to minerals and sediments in the water it extracted from a below-ground well

Case Study: External Surface Damage Repair to Restore Integrity of 400mm GRP Pipe

Areas of external damage on the surface of a 400mm GRP pipe at an oil refinery in Saudi Arabia undergo repair to restore integrity of the line and lessen the chance of future leaks

Case Study: Rapid 5 Minute Epoxy Adhesive Used to Repair Broken Ceramic Teapot Lid

Rapid 5 Minute Epoxy Adhesive accurately repairs a ceramic teapot lid which had broken into two pieces when it was accidentally dropped onto a hard floor

Case Study: Live Leak Pipe Repair of Above and Below Ground Water Supply Pipelines

Water pipes located above and below ground as part of a network servicing a town in Libya required live leak repair to seal cracks without disrupting supplies

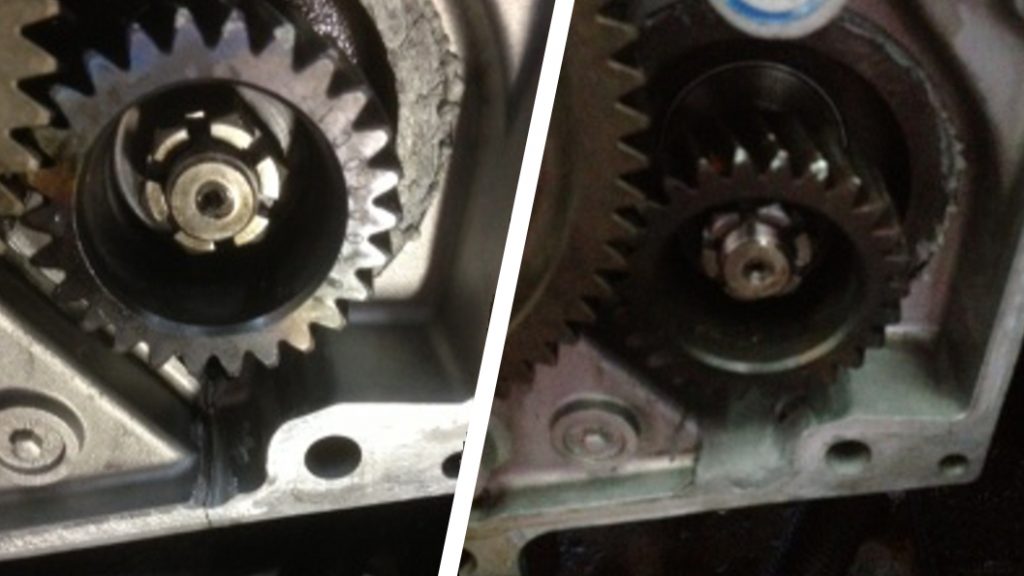

Case Study: Dairy Delivery Truck 466 International Engine Cracked Timing Cover Repair

Industrial Metal saves a Puerto Rico milk company spending $1000 on a new timing cover for one of their delivery trucks by repairing a crack through which oil was escaping

Case Study: Leaking Hydrogen Line Pipe Repair at Power Station in Puerto Rico

Leaking joints at either end of a hydrogen line installed as part of a new cooling system for a Puerto Rico power station required sealing before the pipe went into full service

Case Study: Filler Repair of 50mm Crack Between Toilet Waste Pipe & Bathroom Floor

A hole cut too big into a bathroom floor during renovations left a 50mm crack around the base of a toilet waste pipe, which required permanent sealing with a waterproof filler material

Case Study: Superfast Steel Epoxy Putty Used to Fix Rust Holes on a Classic Car

A classic car owner uses Superfast Steel Epoxy Putty to permanently fix rust holes which had developed on the metal frame of their vehicle in a quick, easy and cost-effective repair

Case Study: Leak Repair of a Bathroom Sink PVC Plastic Drain Pipe

Cracks in a PVC plastic pipe located in a cupboard underneath a bathroom sink undergo a quick and easy DIY repair by the property owner using Superfast Plastic Epoxy Putty Stick