Case Study: 3 Metre Section of Corroded Steel Gas Pipe in CHP System Repair & Refurbishment

An industrial plant in Puerto Rico repair and refurbish a three-metre section of corroded steel pipe carrying natural gas in a combined heat and power system. The line had been damaged by water trapped between the pipe and an incorrectly installed PVC tape, leading to concerns it would weaken to the point of breaching in the near-future.

Case Study Overview

Site Industrial Plant

Location Puerto Rico

Repair Type Pipe refurbishment

Defect Three metre section of corroded 100mm steel pipe in CHP system

Repair Products

Liquid Metal Epoxy Coating, SylWrap Pipe Repair Bandage

Case Study PDF

Case Study Details

The pipeline was 100mm in diameter and ran for 365 metres through the plant, carrying natural gas produced by a combined heat and power system. It was hung on a series of U-shaped supports welded to I-beams suspended from the roof of the building.

When originally installed, the pipe had been wrapped with a protective PVC tape. Unfortunately, incorrect application of the tape had left a three-metre section where it was possible for water and condensation to become trapped between the tape and the line.

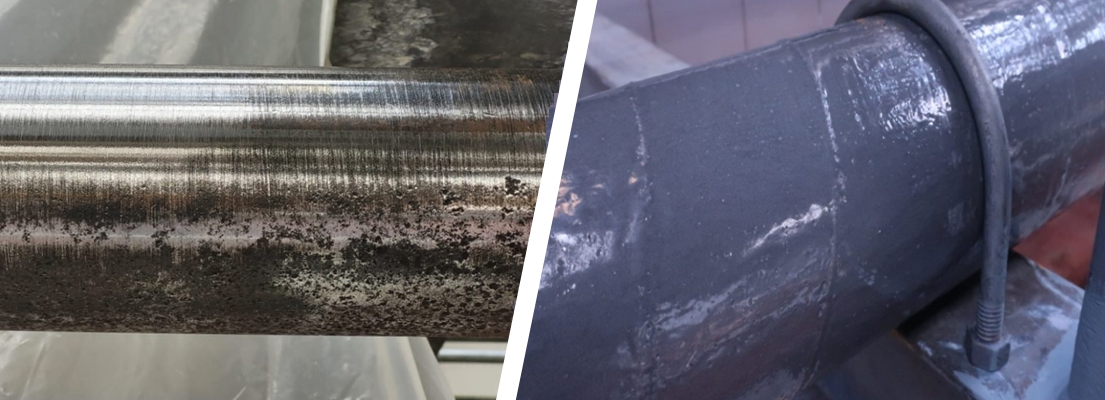

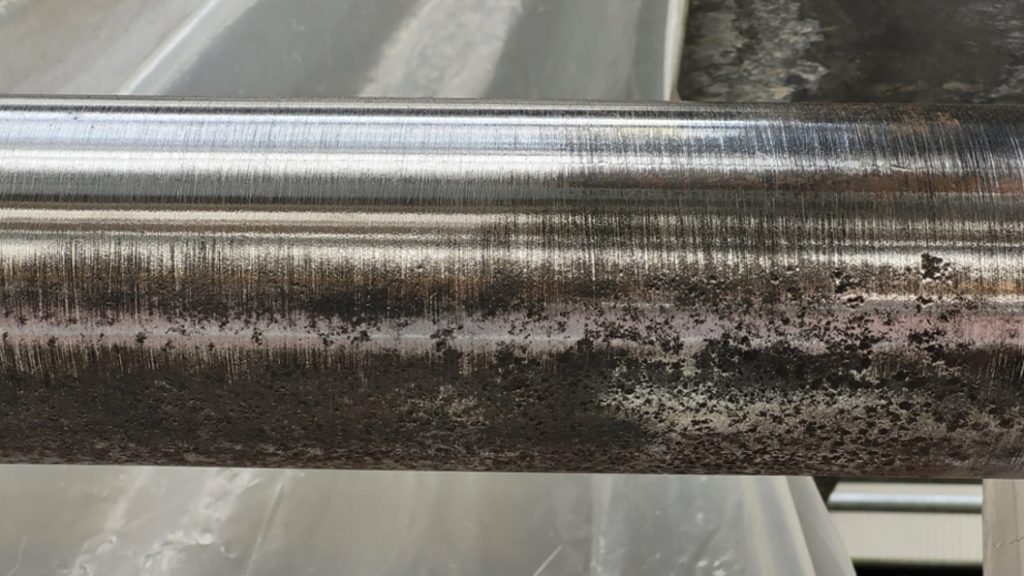

This had caused the line to become heavily corroded, particularly at the bottom of the steel pipe and the area where the section in question rested on its U-shaped support. The weakened three metres of the natural gas pipe now required strengthening and repair before the steel became breached.

The plant decided to use the Sylmasta Pipe Refurbishment System to bring the damaged section of the line back up to specification, by reinforcing the metalwork and giving the pipe greater protection against future corrosion.

First, the U-Shaped support was cut away from the I-beam to enable better access to the corroded area. The PVC tape was removed and rust, grime and paint ground off. Alcoholic cloths were then used to remove any remaining residue from the grinding process.

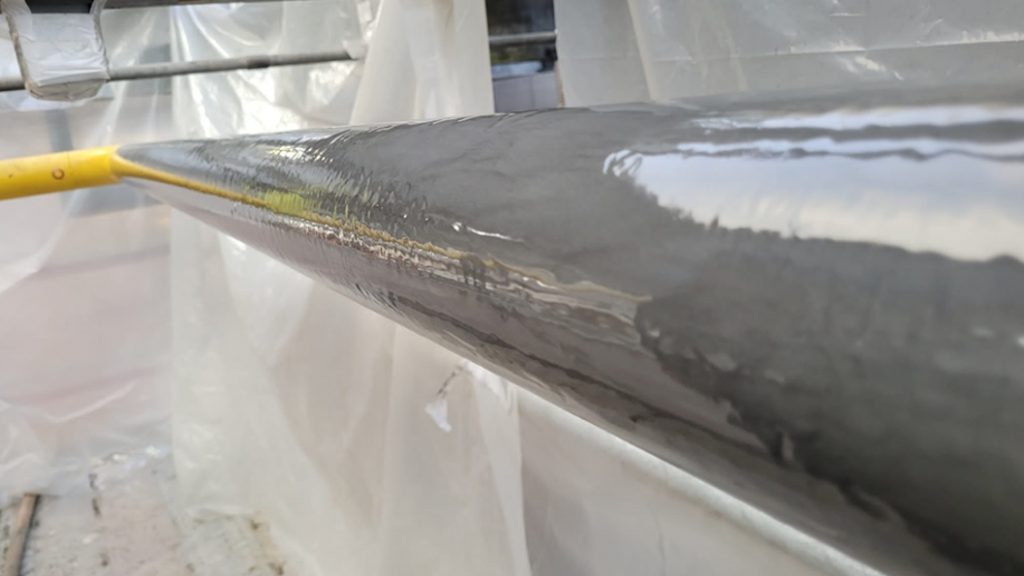

To repair the damage and restore the corroded exterior of the steel pipe, the three-metre section was coated in Liquid Metal Epoxy Coating. Liquid Metal is brush applied and cures to form a smooth, metallic, hard-wearing outer surface which acts as a shield against external corrosion and chemical attack.

The 90-minute gel time of Liquid Metal allowed significant amounts of epoxy to be mixed and painted on without the threat of premature curing. A SylWrap Pipe Repair Bandage was then wrapped around the area of the line which had contact with the U-shaped support.

SylWrap is a composite repair wrap with a water-activated resin. It was applied whilst the Liquid Metal remained tacky and cured within minutes to form a rock-hard, impact resistant outer shell around the pipe. This further increased the thickness of the weakened section and provided an additional layer of protection.

A second layer of Liquid Metal was applied across the three metre section, including over the SylWrap. Although an additional coating on top of the composite bandage is not a required step of the Sylmasta Pipe Refurbishment System, the plant wanted to make the line look aesthetically pleasing with a final metallic finish.

Once the pipe had been refurbished, the removed U-shaped support was welded back to the I-beam. The line was then fixed to the U-shape via a new pipe support clamp fitted to prevent movement caused by vibration. The clamp was also coated in Liquid Metal.

Refurbishing the pipe was carried out with no impact to operations at the plant. It prevented an expensive and disruptive future repair or replacement being needed when corrosion eventually ate through the line.

The plant were very happy with the outcome and how easy their maintenance team found the application. They are now intending to use Liquid Metal to extend the lifespan of other pipes and structures at both this facility and across other sites.

Products Used

Liquid Metal

Epoxy coating brush applied to form a new metallic surface over the damaged pipe

SylWrap Pipe Repair Bandage

Water-activated wrap which reinforces pipes by increasing thickness of weakened sections

Related Case Studies

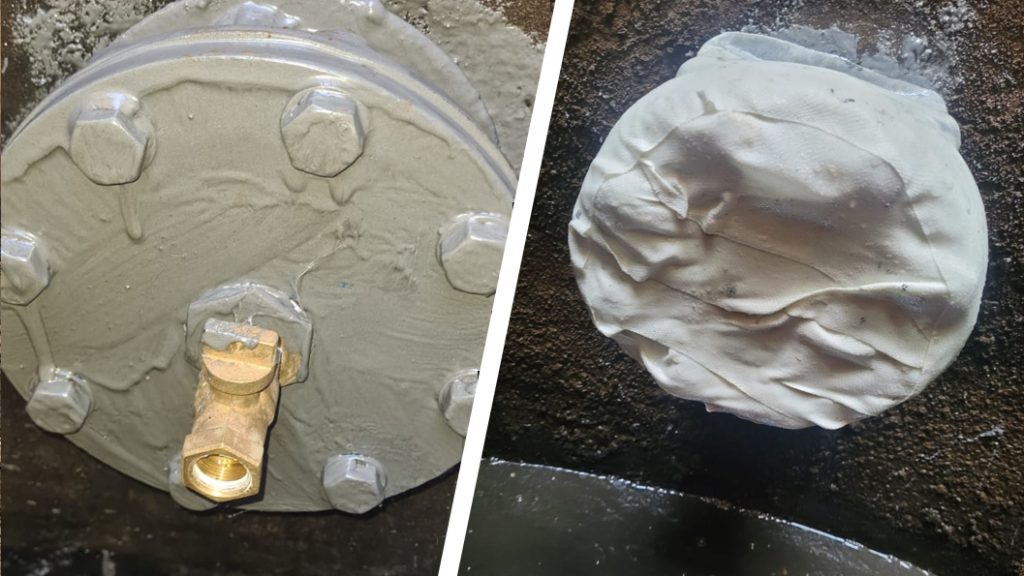

Case Study: Pipe Capping of Decommissioned Underground Drainage System at Landfill Site

Case Study: Permanent Anti Slip Solution to Protect Workers When Standing on Helicopter Skids

Case Study: Repair & Refurbishment of Corroded 20 Metre Long Porth Pipe Bridge

Case Study: Liquid Metal Lays Anti Slip Flooring Surfaces at PepsiCo Plant in Chile

Case Study: Reinforcement of Weakened 22 Degree Cast Iron Pipe Elbows

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com