Case Study: Industrial Metal Repairs a Large Gouge to Refurbish a Drill Stand

Drill and fill – Industrial Metal is used to rebuild and refurbish a badly damaged second-hand drill base stand

An engineer uses Industrial Metal Epoxy Paste to rebuild and refurbish a second-hand drill base stand with a large gouge caused by the previous owner’s misuse at a fraction of the cost of buying new.

Case Study Data

Repair Type

Metal repair and refurbishment

Defect

Large gouge in a drill base stand

Products Used

Industrial Metal Epoxy Paste

Epoxy paste used to fill the significant gouge suffered by the drill base

Case Study PDF

Case Study Review

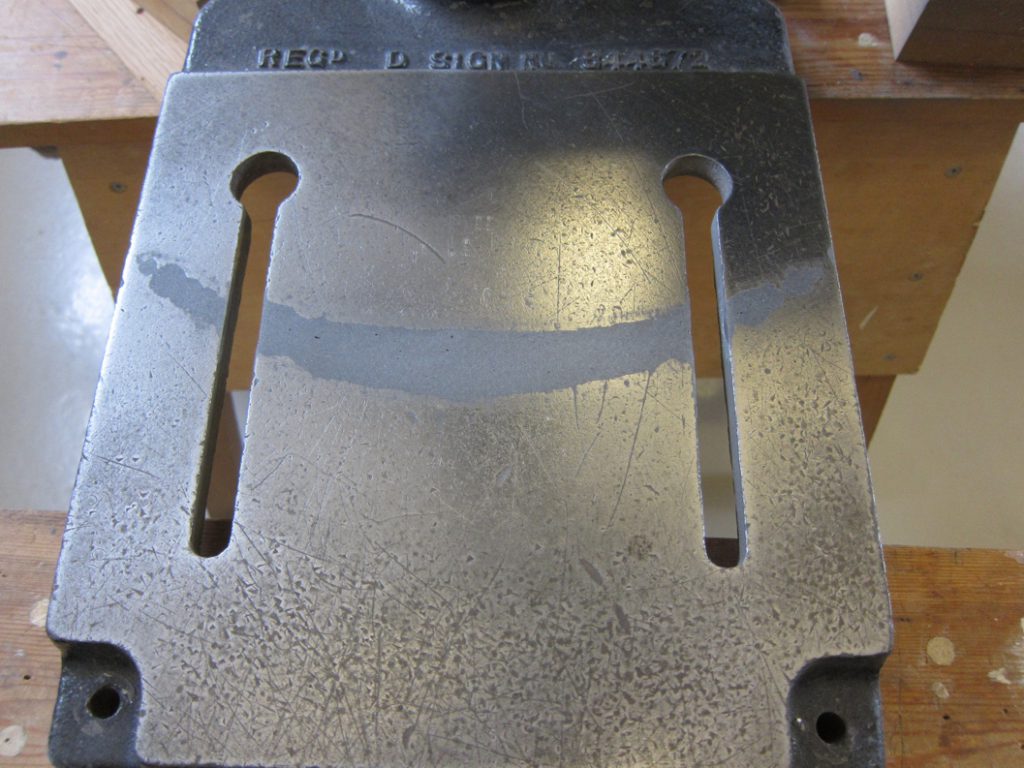

The stand was suffering from a significant gouge where the drill had frequently been allowed to penetrate the base by the previous owner, who as a result had subsequently decided to sell the stand.

It was otherwise in good condition, meaning that if the engineer who bought the stand could refurbish it, then he would have a working second-hand drill base at a fraction of the cost of purchasing new stock.

After consulting Sylmasta, it was decided that Industrial Metal Epoxy Paste would be the most suitable material for filling in the gouge and returning the base to close to its original state.

Industrial Metal is thixotropic, meaning it will not sag. It is virtually odourless, with no unpleasant smell compared to other epoxy pastes.

It is temperature resistant to 130°C and reinforced with corrosion-resistant metal platelets, giving it a smoother finish than regular epoxy repair pastes when machined.

The gouge in the stand requiring repair had penetrated right through the base. To prevent the Industrial Metal falling onto the floor as it was applied, a wooden plate was placed underneath the gouge.

Further wood was used to ensure that the necessary gaps included as part of the base’s design did not inadvertently become filled by the epoxy paste.

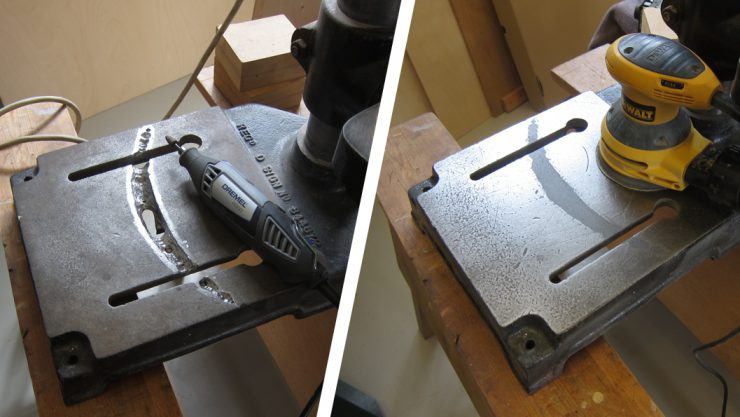

Before using Industrial Metal, the drill base had to undergo a degree of preparation. All traces of rust and grime were removed from the surface, which was then roughed up using abrasives.

Industrial Metal was applied as soon as the preparation stage was complete. The epoxy paste was pushed into the gouge using a hand tool, with the work time of 60 minutes allowing more of the paste to be mixed and applied without the threat of premature curing.

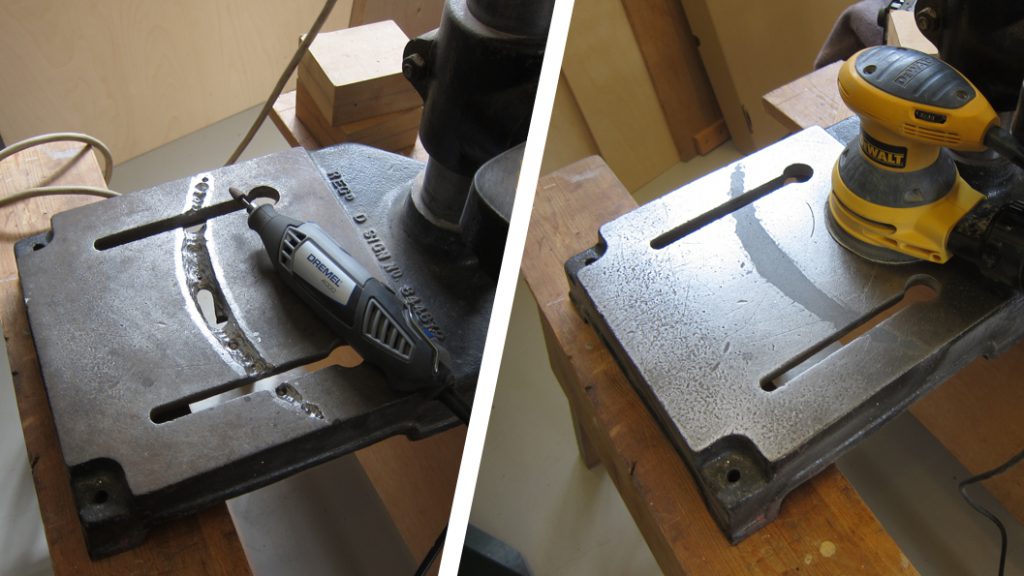

A full cure was achieved in 24 hours, after which the surface of the drill stand was sanded down to provide an ultra-smooth finish which was seamless with the rest of the base. The rebuild using epoxy paste had been a complete success.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com