Case Study: Trenchless Pipe Installation Protection of 150mm Steel Natural Gas Pipeline

Czech mate – SylShield protection enables the installation of a natural gas pipeline in Czechia via Horizontal Directional Drilling

In its first deployment in the field, SylShield was used for the protection of welded joints on a 150mm diameter steel pipeline carrying natural gas when it was rerouted beneath a road and river via horizontal directional drilling, a form of trenchless pipe installation.

Case Study Data

Site

Natural gas pipeline

Location

Czechia

Repair Type

Pipe and weld protection

Application

Protecting 150mm steel pipeline undergoing trenchless installation via horizontal directional drilling

Products Used

SylShield Pipe & Weld Protection Wrap

Composite repair wrap three times thicker than standard SylWrap HD for protecting pipes during trenchless installation

Case Study PDF

Case Study Details

Horizontal directional drilling involves connecting together sections of a pipeline above ground via welding or a similar process, digging a borehole and pulling the completed line through to install it.

This removes the need to dig huge and disruptive trenches across vast swathes of land. It also allows pipes to be installed beneath roads, rivers, seas and other areas which would otherwise be challenging to pass. In some cases, pipes many kilometres in length are dragged through the ground and installed using horizontal direction drilling.

The high-pressure natural gas pipeline in the south of Czechia was being rerouted to improve energy security for the country. It was to pass under a local road and stream, meaning that horizontal directional drilling was the most suitable form of trenchless installation.

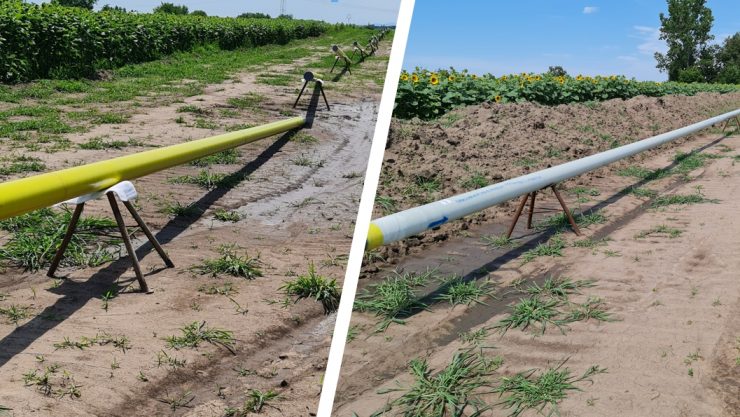

Pipes undergoing trenchless installation are given protection against the potential damage caused by dragging them underground. The 150mm diameter steel pipe being used in this application was coated in both epoxy and a 3mm thick fibreglass composite.

Joins on the pipe are more challenging to protect. The points at which sections are welded together cannot be covered with epoxy, fibreglass or any other type of factory applied protection. This is where SylShield came in.

The company installing the line were a long-time client of Sylmasta. They got in contact to ask if there was a potential solution for protecting the joints in the pipe, in addition to the heat shrink sleeves used as standard.

SylShield Pipe & Weld Protection Wrap is the toughest, most robust composite wrap in the SylWrap range three times the thickness of a standard SylWrap HD Pipe Repair Bandage. It has been specifically designed for the protection of pipelines during trenchless pipe installation.

Working to a tight deadline, Sylmasta were able to produce the required number of SylShield wraps at their factory in England on the Thursday and deliver them to Czechia. The installation team collected the products from a DHL depot on Monday morning and set to work immediately.

Each welded joint and heat shrink sleeve was overwrapped with SylShield. The resin was activated with water and SylShield wrapped and smoothed around the pipe. Within minutes, it cured to form a rock-hard sleeve encompassing the joint to protect it from the rigours of horizontal directional drilling.

As each section was wrapped with SylShield, shrink wrap was applied over the top to secure the composite against the pipe and improve lamination. The shrink wrap was then spiked, ensuring that the carbon dioxide released during the curing of SylShield could escape rather than becoming trapped.

By Monday evening, the entire line had been welded together, protected with SylShield and pulled through the borehole under the road and stream to complete the trenchless installation. Sylmasta had played a small but important part improving natural gas supplies to Czechia.

Afterwards, the team leader responsible for the project emailed to say: “The installation was a success and we particularly appreciated the timely delivery of the SylShield wraps. Big thanks to Sylmasta for meeting the tight deadline, which even we thought would be unrealistic.”

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com