Industrial Metal Epoxy Paste

Industrial Metal is a metal-filled epoxy repair paste reinforced with corrosion-resistant platelets. It protects and reinforces metalwork, fills large holes and cracks, and repairs areas of pitting. In pipe repair applications, Industrial Metal rebuilds and strengthens degraded pipelines by increasing outer wall thickness.

Where corrosion, chemical attack or other environmental factors have weakened the exterior of a pipe, Industrial Metal is applied to rebuild pipeline thickness back towards original specification. It fills damage caused by impact and pitting, restoring surface profile.

The corrosion-resistant platelets provide excellent protection for surfaces from corrosion and chemical attack, whilst also giving it a smoother finish than regular epoxy pastes when machined. Industrial Metal cures on wet surfaces. As well as metalwork, it can be applied to most plastics and wood.

Industrial Metal has been independently tested to BS 6920 standard, meaning when used in conjunction with a SylWrap Pipe Repair Bandage, it is certified to British standards as safe to use on pipes carrying drinking water.

Away from pipeline applications, it is used to repair and protect pumps, metal castings, automotive bodywork and fills large gaps and gouges.

A 60-minute gel time allows for large quantities to be mixed and carefully applied without the threat of premature curing. Because of its work time, Sylmasta recommend Industrial Metal for applications at higher ambient temperatures.

Industrial Metal Epoxy Repair Paste Details

Before applying Industrial Metal, surfaces should be free of paint, rust and grime. The substrate should then be roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Industrial Metal should be applied as soon as the preparation procedure is completed. Part A and Part B are mixed together at a 2:1 ratio by weight or volume.

The epoxy paste is then spread over the area requiring repair using a putty knife. Industrial Metal should be pushed in firmly to ensure maximum contact and to avoid trapping air between the paste and the surface.

When adding SylWrap Pipe Repair Bandage for pipe repair applications, the bandage is wrapped over Industrial Metal as soon as the epoxy paste has been applied. SylWrap will provide a rock-hard, impact resistant layer of protection, further strengthening the weakened section of pipeline.

Industrial Metal has a gel time of 60 minutes. It achieves a full cure in 24 hours. It is thixotropic, meaning it will not sag.

It is virtually odourless, with no unpleasant smell compared to other epoxy pastes. Its light consistency makes it easier to mix than stiff, heavy traditional epoxy pastes.

Industrial Metal is temperature resistant to 130°C. For repairs to pipework exposed to extreme temperatures in excess of 130°C, please see Titanium Supergrade HT Epoxy Paste.

Benefits of Industrial Metal Epoxy Paste

- Cures underwater and on wet surfaces

- Does not shrink and can be machined

- Easy to mix and apply with a long working time for complex repair jobs

- Increase resistance against corrosion and chemicals

- Tested to BS 6920 standard

- Bonds to metal, most plastics and wood

Applications

- Steel pipe repair, iron pipe repair, copper pipe repair, PVC plastic pipe repair, GRP pipe repair

- Restoring surface profile for improved pipeline integrity

- Metal repair, chemical protection and corrosion protection

- Filling holes, gaps and gouges

- Rebuilding worn and damaged parts

- Underwater repairs

- Used in petrochemical plants to repair and strengthen pipes, fittings and equipment

- Repairing industrial equipment, tanks and worn areas in pumps and valves

Technical Data

| Data | |

| Work Time | 60 minutes |

| Full Cure | 24 hours |

| Shore D Hardness | 85 |

| Compressive Strength | 82 MPa |

| Max Service Temp | 130°C |

Product Codes

| Code | Paste Quantity |

| PST-500g | 500g |

| PST-4x500g | 2kg (4 x 500g) |

| PST-2kg | 2kg |

| PST-5kg | 5kg |

| PST-25kg | 25kg |

| PST-50kg | 50kg |

TDS Downloads

Industrial Metal Epoxy Paste Case Studies

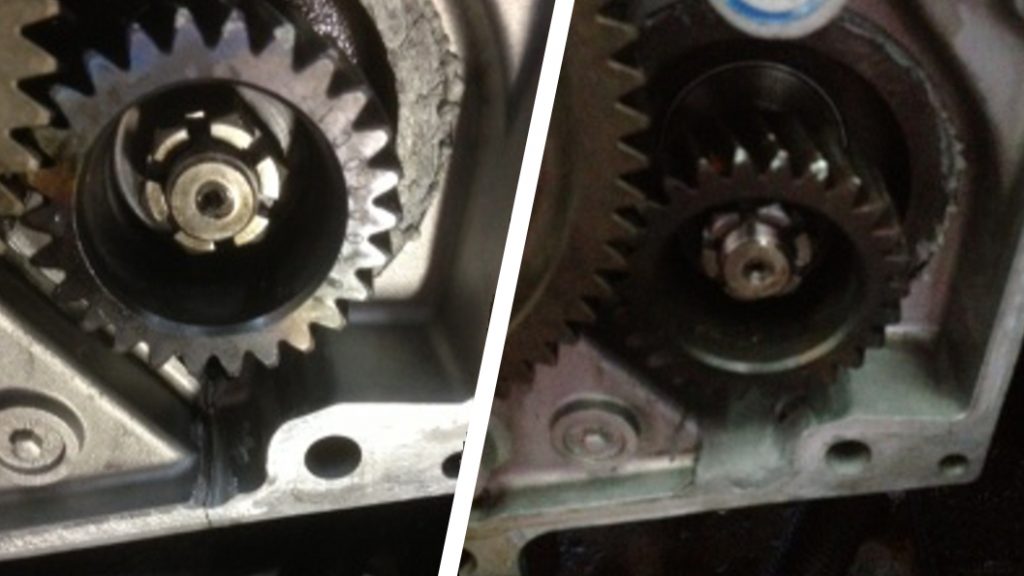

Case Study: Dairy Delivery Truck 466 International Engine Cracked Timing Cover Repair

Case Study: Reinforcement of Weakened Pipe Elbow Joint on 100mm 22 bar Sulphuric Acid Line

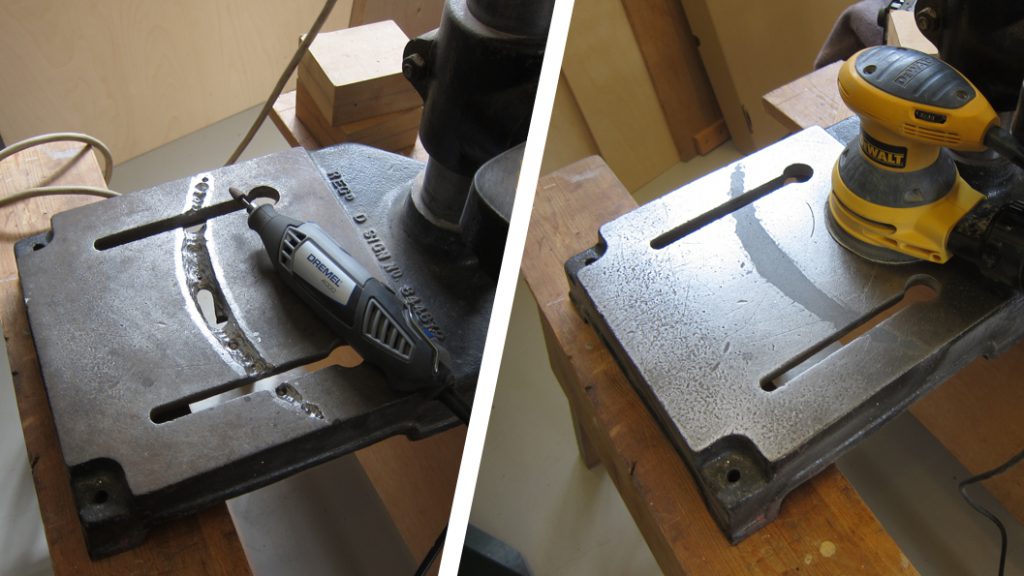

Case Study: Industrial Metal Repairs a Large Gouge to Refurbish a Drill Base Stand

Please use the form to enquire about the price and availability of

Industrial Metal Epoxy Paste

Related Metal Repair Products

Titanium Supergrade HT Epoxy Paste

Alloy-filled epoxy paste with very high compressive strength and extreme temperature resistance. It is used for the repair and maintenance of systems operating in environments up to 250ºC and stress-bearing equipment including shafts, keyways and splines.

Work Time: 180 minutes

Functional Cure: 16 hours

Max Service Temp: 250ºC

Superfast Steel Epoxy Putty Stick

Steel-filled epoxy putty in an easy-to-use, pre-formatted 114g stick with WRAS approval for use with potable water. It has a 3-minute work time for making rapid repairs and filling damage to pipework, parts and machinery made from steel, iron and other ferrous metals.

Work Time: 3 minutes

Functional Cure: 1 hour

Max Service Temp: Up to 150ºC

Versatile, metal-filled coating with a wide range of repair, refurbishment and maintenance uses. It offers excellent protection against corrosion and chemical attack, curing to form a protective outer shield around pipework, equipment, machine parts and surfaces.

Work Time: 90 minutes

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC