SylWrap Universal Pipe Repair Kit – For Live Leaks

The SylWrap Universal Pipe Repair Kit permanently seals a burst or leaking pipe in under 30 minutes, even when pressure cannot be turned off. It enables any user to make a WRAS approved live leak repair to steel, stainless steel, iron, copper, PVC, GRP, clay, ceramic, concrete, lead and rubber pipes by following a simple two-stage process.

Because flow does not need to be isolated when using a Universal Kit, the draining of pipelines or tanks is not required before repair. This avoids time-consuming shutdowns of equipment and provides a cost-effective alternative to replacement.

Repairs can be built to have pressure resistance up to 30 bar, are temperature resistant to 120ºC and effective on pipes carrying hot and cold water and chemicals. WRAS approval means the Universal Kit is certified as safe to use on pipes carrying drinking water.

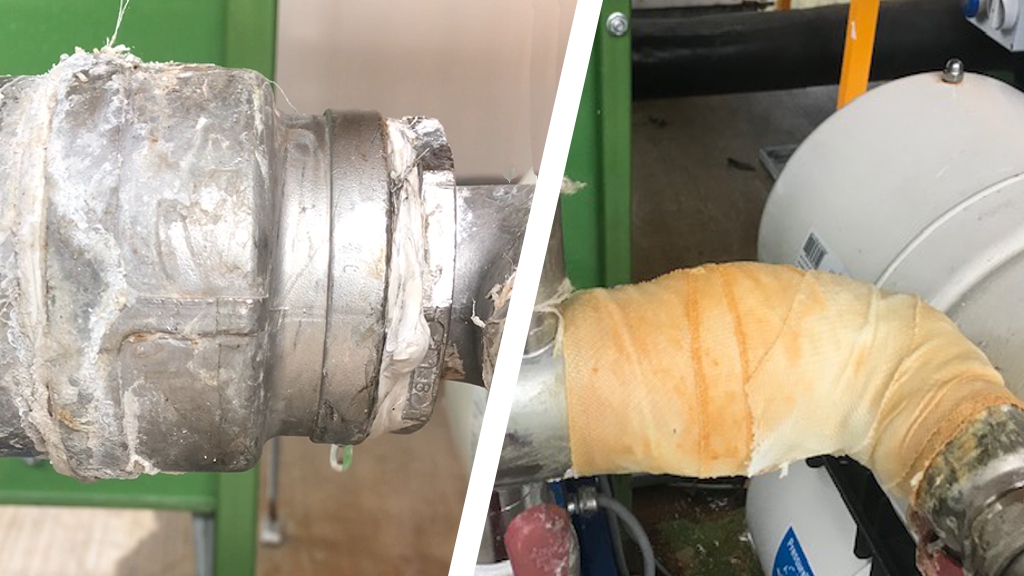

Effective repairs can be made around difficult elbow joints, tee joints and welded joints, offering a more flexible and versatile option compared to heavy, bulky pipe repair clamps.

No operational training is required to use the Universal Kit. Its applications vary from small-scale domestic plumbing repairs to sealing pipeline leaks in vast oil refineries in Iraq. Several UK water companies use Universal Kits to repair live leaks on the public supply network.

Other industries where Universal Kits are found include quarries, mines, wastewater treatment, district heating, agriculture, petrochemical plants, oil rigs, nuclear power stations, freight ships, super yachts and within public buildings including hospitals, hotels and airports.

SylWrap Universal Pipe Repair Kit details

The Universal Kit contains Superfast Epoxy Putty Stick, Wrap & Seal Pipe Burst Tape and SylWrap Pipe Repair Bandage for fixing leaking pipes.

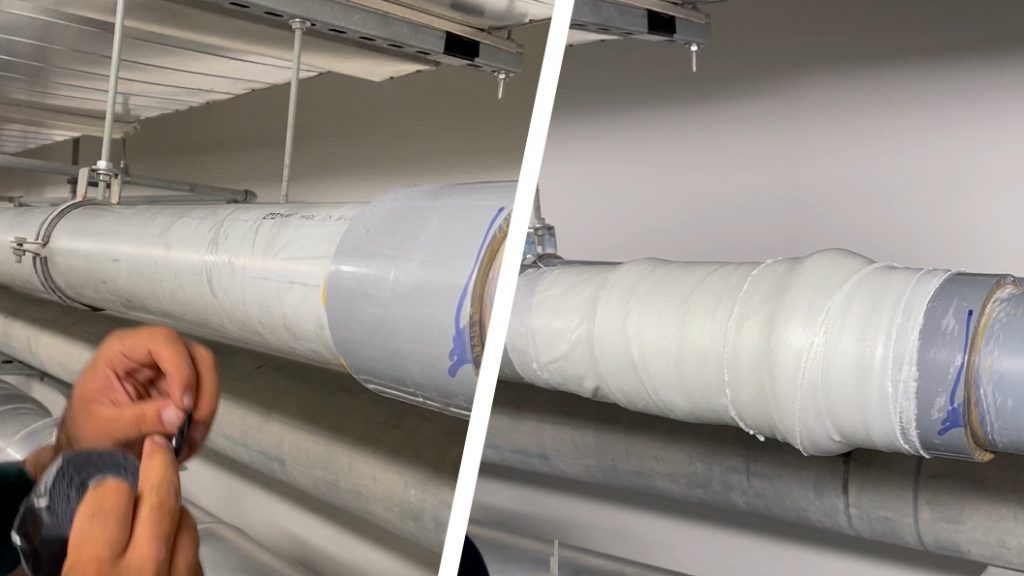

If pressure cannot be turned off, Wrap & Seal is used to seal the leak. The waterproof repair tape is made from self-amalgamating silicone which stretches by 300 percent.

When wrapped around pipes, it will bond to both the substrate and itself. Once fused, it forms a solid rubber band maintaining pressure over the leak, thus sealing it.

Each Universal Kit comes with one Wrap & Seal Tape. For high pressure industrial repairs, further Wrap & Seal may be required to build up pressure resistance. Multiple tapes applied over each will fuse together in the same way, capable of creating a repair with resistance as high as 30 bar.

If you are undertaking such a high-pressure application, then please go to the Repair Calculator tab and enter information about your repair to determine the number of tapes needed. Additional Wrap & Seal can be purchased separately.

Universal Kits covering pipes over 150mm diameter include a SylPad Pressure Resistance Multiplier. SylPad is used with Wrap & Seal to better concentrate the pressure of the Tape directly over the leak on larger pipes

If pressure can be turned off, Superfast Epoxy Putty is used to seal the leak. To use a Superfast Epoxy Stick, you cut off the amount of putty required and mix it by hand until it turns a uniform colour.

It is then pushed into the hole or crack requiring repair. Within 5–10 minutes, the putty will harden to fill the damage with a watertight material. Repairs made using Superfast Putty are resistant to 30 bar.

The second stage of the repair sees the initial sealant overwrapped with SylWrap Pipe Repair Bandage. SylWrap is a fibreglass repair wrap with a water-activated resin. When wrapped and smoothed over the sealed leak, it will set rock-hard to provide an impact resistant, protective shell.

For regular pipe repair users, Sylmasta have developed the SylWrap Contractor Case containing enough products for up to six pipe repairs. The Case is easy to store either on the van or on site and works out at a cheaper cost-per-repair than buying individual Pipe Repair Kits.

Engineers equipped with a Case have everything readily available to repair burst and leaking pipe as soon as problems are identified, reducing the amount of precious water lost.

Benefits of a SylWrap Universal Pipe Repair Kit

- Allows the user to carry out an emergency pipe repair in 30 minutes with no training needed

- Repairs live leaks, negating the need for turning off systems

- Offers a low-cost alternative to hiring a contractor or seeking replacement parts

- Increases pressure resistance, chemical resistance and longevity of pipes

Applications

- Copper pipe repair, PVC plastic pipe repair, steel pipe repair, iron pipe repair, GRP pipe repair, ceramic pipe repair, concrete pipe repair, lead pipe repair, rubber pipe repair

- Fixing leaking bathroom, kitchen and other household pipes

- Pipe repairs at wastewater treatment works, quarry wash plants, dry risers, petrochemical plants, nuclear power plants, oil rigs and breweries

- Repairing pinholes, cracks and leaking joints

- WRAS approved for repairs to pipes carrying drinking water

Technical Data

| Data | |

| SylWrap Work Time | 2–5 minutes |

| Functional Cure | 30–45 minutes |

| Full Cure | 24 hours |

| Cured Material Life | 10–20 years |

| Max Service Temp | 120°C / 250°F |

| Max Pressure Resistance | 30 bar |

Product Codes

Please see Pipe Size Guide Tab for SylWrap Universal Pipe Repair Kit product codes

TDS Downloads

SylWrap Universal Pipe Repair Kit Size Guide

The below guide details the size of SylWrap Pipe Repair Bandage and Wrap & Seal contained within each Universal Pipe Repair Kit, whether it contains a SylPad Pressure Resistance Multiplier and the diameter of pipe each Kit is designed to repair.

| Product Code | SylWrap Bandage Size | Wrap & Seal Size | Includes SylPad | Repairs Pipe Diameter |

| SYL-106-UP | 25mm x 1.8m | Small 25mm x 4m | No | Up to 15mm |

| SYL-206-UP | 50mm x 1.8m | Small 25mm x 4m | No | 15 – 25mm |

| SYL-212-UP | 50mm x 3.6m | Small 25mm x 4m | No | 25 - 50mm |

| SYL-309-UP | 75mm x 2.7m | Small 25mm x 4m | No | 25 – 50mm |

| SYL-312-UP | 75mm x 3.6m | Small 25mm x 4m | No | 50 – 75mm |

| SYL-412-UP | 100mm x 3.6m | Small 25mm x 4m | No | 50 – 100mm |

| SYL-416-UP | 100mm x 5.0m | Small 25mm x 4m | No | 75 – 125mm |

| SYL-616-UP | 150mm x 5.0m | Small 25mm x 4m | No | 100 – 150mm |

| SYL-633-UP | 150mm x 10.0m | Large 50mm x 4m | Yes | 150 – 300mm |

| SYL-866-UP | 200mm x 20.0m | X-Large 50mm x 11m | Yes | 300 – 600mm |

Wrap & Seal Repair Calculator

The below Wrap & Seal Calculator can be used to determine the recommended number of Wrap & Seal Pipe Burst Tapes required to seal a live leak based on pipe diameter and pressure.

Enter the diameter of the pipe in millimetres, water pressure and the size of the hole requiring sealing in millimetres. The safety factor is a multiple to include a margin of safety. For example, if pipe pressure is 5 bar and you want a safety factor of two, the calculator will formulate a repair capable of withstanding 10 bar.

After entering your data, selecting the size of Wrap & Seal will determine how many of that specific tape are required for your repair. Repairs being made to pipes in excess of 150mm diameter using Wrap & Seal PB-50x4m or PB-50x11m should be made in conjunction with SylPad.

Each Universal Kit comes with one Wrap & Seal. If the Calculator determines that you need more than one Wrap & Seal for your repair, consider using additional tapes.

Calculations serve as a guide to potential maximum pressure resistance only. Actual pressure resistance depends upon pipe material, condition, hole size, leak type and tension maintained during wrapping. If you are unsure, more than one Wrap & Seal can be used to stop the leak.

SylWrap Universal Pipe Repair Kit Case Studies

Case Study: Live Leak Repair of 150mm Cement Coated Steel Pipe on Water Network in Mexico

Case Study: Repair of Leaking Stainless Steel Pipe Inside Farm Biodigester Tank

Case Study: Live Leak Pipe Repair of Above and Below Ground Water Supply Pipelines

Case Study: Steel District Heating System Pipe Suspended in Ceiling Live Pinhole Leak Repair

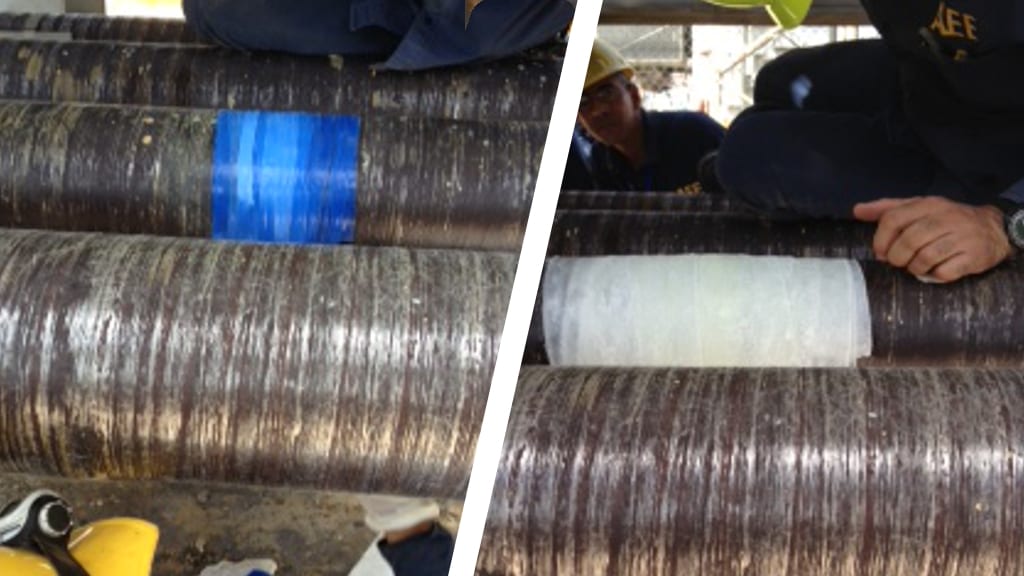

Case Study: Live Leak Pinhole Repair on 150mm Elbow at Pumping House in Malaysia

Case Study: Repair of a Leaking 200mm Fuel Oil Line Pressure Resistant to 44 bar in Libya

Case Study: Bahrain International Airport Repair of Leaking Step Joint on 100mm UPVC Pipe

Case Study: 650mm Ductile Iron Pipe Located in Pit Undergoes Live Leak Coupling Joint Repair

Case Study: Live Leak Repair of a Cracked 4 bar 250mm PCCP Pipe Stub in Saudi Arabia

Case Study: Emergency Repair of Hospital 300mm Air Conditioning Pipe on Hottest Day of June

Case Study: Buried 600mm Asbestos Cement Pipe Leaking Sleeve Repair in Mexico

Case Study: Repair of an 80mm Split to a Plastic Hose Supplying Water to a Pond

Case Study: Leak Repair & Encapsulation of a Steel & Iron Welded Pipe Joint

Case Study: Stainless Steel Pipe Repair Inside a Biomass Plant Heating Tank

Case Study: Argentina Oil Well 900mm Steel Pipe Surface Restoration & Repair

Case Study: Heavily Corroded Pipe Repair Keeps a District Heating System Running

Case Study: Repair and Reconnection of a Ruptured 20bar Cast Iron Water Supply Pipe

Case Study: Repair of a Cracked PVC Pipe in a Swimming Pool Filtration System

Case Study: Underground Heating Pipe with Insulation Lagging Repair on a Farm

Case Study: High Temperature Live Leak Pipe Repair in an on-site CHP Plant

Case Study: Repair of a Cracked Contaminated Water Pipe in a Puerto Rico Power Station

Case Study: Burst Underground Water Main is Repaired After 15 Years of Leaking

SylWrap Universal Pipe Repair Kit Videos

High pressure live leak repair on a steel pipe

A live leak demonstration at a water utility company’s depot carried out as part of the Sylmasta Pipe Repair Roadshow 2020.

Live leak repair on a 150mm elbow joint

A pinhole live leak repair carried out on a 150mm steel pipe elbow joint at a pumping house in Malaysia.

Live leak repair on a 95mm steel pipe

A test live leak repair carried out to a 95mm steel pipe at Sylmasta HQ in the UK.

Please use the form to enquire about the price and availability of the

SylWrap Universal Pipe Repair Kit

Related Pipe Repair Kits

SylWrap Standard Pipe Repair Kit

The Standard Pipe Repair Kit contains Superfast Epoxy Putty and SylWrap Bandage. It makes a single, WRAS approved, permanent repair to a leaking pipe where pressure can be turned off.

Live Leaks: No

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

SylWrap Pipe Repair Contractor Case

For regular users like water companies, the Contractor Case is stored on-site or on-the-van for fast response as soon as leaks are identified. It makes up to six WRAS approved, permanent live leak repairs.

Live Leaks: Yes

Number of Repairs: Multiple

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC